There are many jobs in which chemical water tanks are extremely important for preserving water. These tanks hold chemicals that, when added, allow water to be cleaned and made safe for use. “These chemical water tanks made it a hundred times easier to prevent people from getting sick,” says King.

Chemical water tanks do a great job in many situations such as washing waters. These custom water tanks plastic are designed to contain and blend the chemicals necessary for treating water and removing dirt. By using chemical water storage tanks, businesses can ensure the water they use is fit for purposes such as manufacturing products, farming and public services.

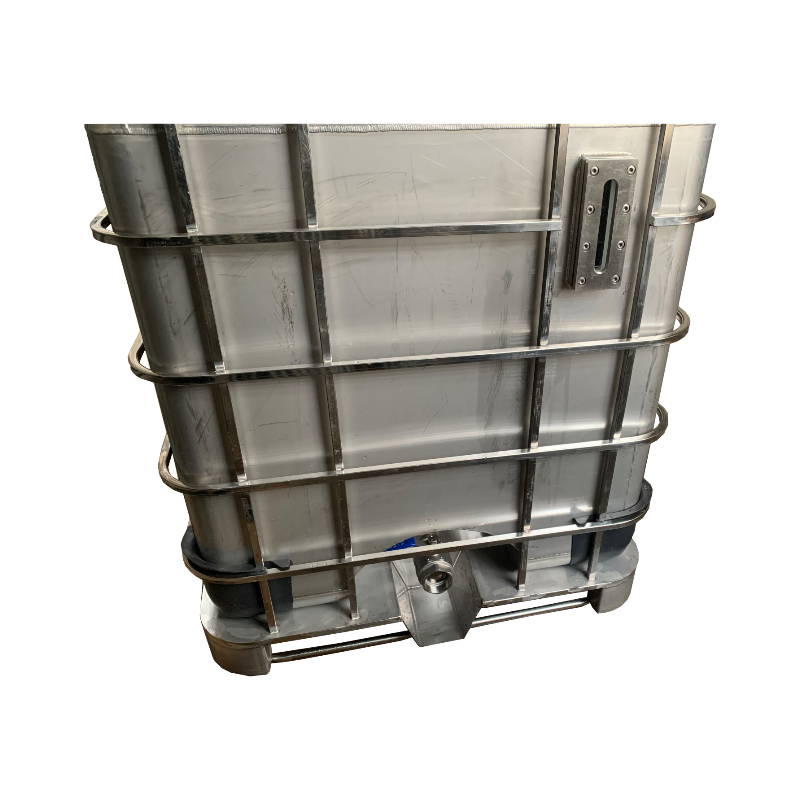

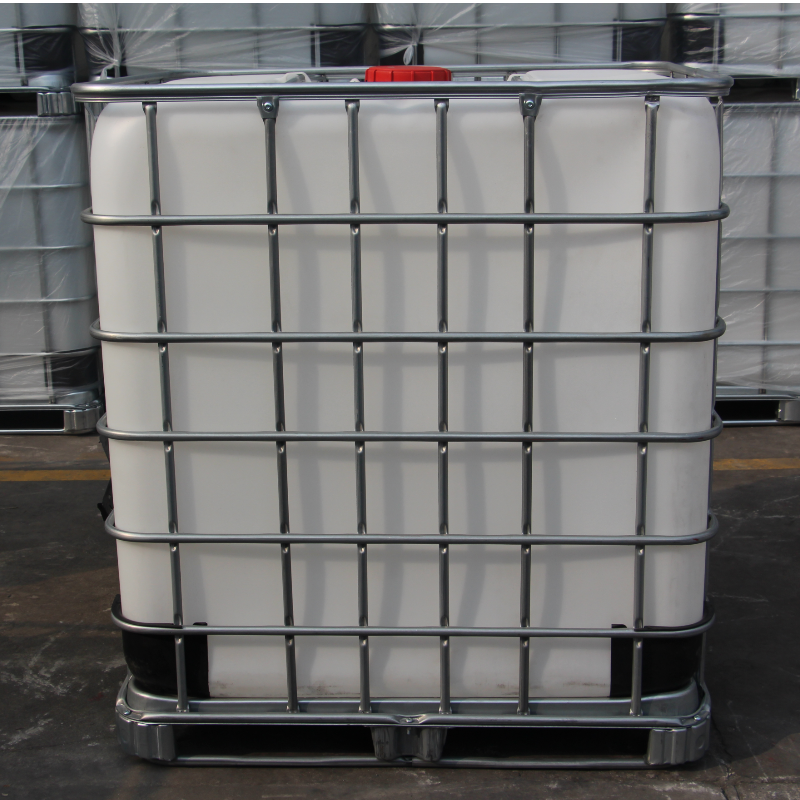

When choosing a chemical water tank, there are a few important things to consider. One big one is the type of material the tank is constructed from. Choosing A Tank When you are looking for a stainless steel water tank, it’s great to find one that is durable and safe so it can keep and mix chemicals without either being tainted or breaking. Also consider the size and shape of the tank, so it fits in the space you have for it, and that it holds enough water.

Looking after your Derksen chemical water tank It’s crucial to maintain the cleanliness of your chemical water tank for it to last longer. You’ll want to inspect it regularly for any damage, such as cracks or leaks. Also, regularly clean the tank to remove accumulated chemicals or dirt, which could interfere with the way it operates. Storing and handling your chemicals as specified will go a long way toward maintaining the metal water tank and keeping it working properly.

Chemical water tanks are essential in the water treatment process by storing and blending chemicals used to purify water. These Derksen tanks introduce chemicals such as chlorine or fluoride in water to kill germs and take away dirt. Water treatment plants can use chemical water tanks to ensure the water coming into their facilities is safe to drink.

Chemical water tanks can be found in a variety of materials each having its pros and cons. These Derksen ibc water tank are made of different materials that may include fiber glass, plastic, or stainless steel. Fiberglass tanks are light and tough, which is great for exterior use. Plastic tanks are less expensive, and do not rust, so they are popular. Stainless steel tanks are durable and resistant to chemical damage, but they may cost more than other types.

Our factory covers an area of 10,000 square meters.We have Numbers Of Bending Machine, Punching Machine, Laser Cutting Machine, Automatic Argon Arc Welding Machine,Meet All Kinds Of Customer Customization Requirements. The production capacity can reach 100 units per day

We have an excellent service team. It includes sales, production, quality inspection, logistics, after-sales and other departments to ensure the best and quickest completion of customer orders.

We have a complete product supply chain, from stainless steel raw material opening, stamping, cutting, bending, welding, assembly, we are independently completed.

We possess 90% self-produced products, allowing us to control costs from the source,.We have 10 years of experience in the productionAnd serving more than 20 countries and regions .