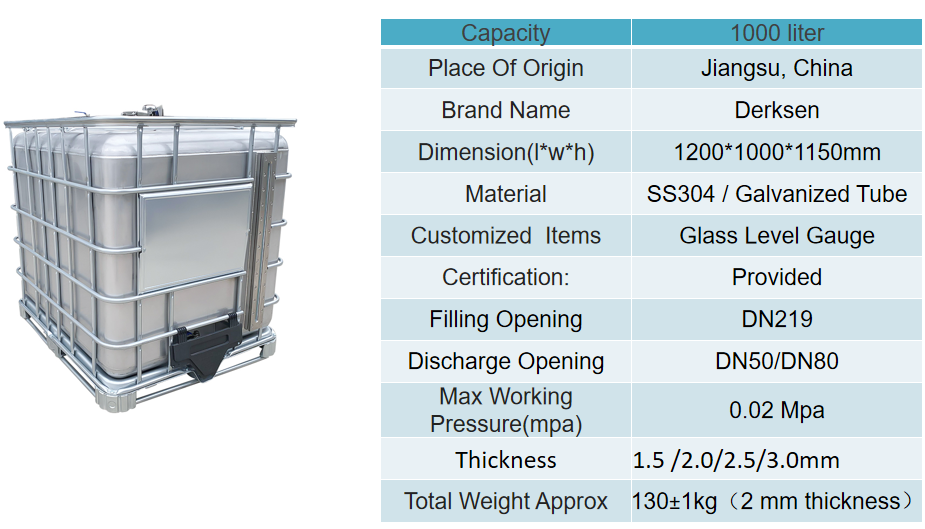

The cover plate of this stainless steel tank is made of 304 stainless steel plate by a one-time stamping mold, Eight Vertex Angles without splicing welds, the cover plate has a reinforcement design, and the side plate is welded with the cover plate after bending. The welding process is TIG welding. With a capacity of 1000 litres, it is designed for the safe storage and transport of liquid or granular materials.

SS TANK 1000L WITH GLASS LEVEL GAUGE DESCRIPTION

The cover plate of this stainless steel tank is made of 304 stainless steel plate by a one-time stamping mold, Eight Vertex Angles without splicing welds, the cover plate has a reinforcement design, and the side plate is welded with the cover plate after bending. The welding process is TIG welding. With a capacity of 1000 litres, it is designed for the safe storage and transport of liquid or granular materials.

The outer frame is made of galvanized round pipe by automatic welding, and SS304 stainless steel outer frame can also be customized. The outer frame can be stacked, and reused.

This SS tank is equipped with atmospheric manhole and vent valve at the top, and standard discharge valve at the bottom to support fast emptying.

Manhole and valve size can be customized,The SS tank combines durability, safety and economy with a service life of more than 10 years, making it an ideal alternative to traditional plastic tank.

The explosion-proof glass level guager is specially used in flammable and explosive environments (such as petroleum and chemical industry). It is composed of high-strength explosion-proof glass, stainless steel flanges and gaskets. It shows the liquid level directly through transparent glass and has the characteristics of corrosion resistance, high temperature resistance (- 80C ~ 400C), pressure resistance (≤ 10MPa), tight sealing and leakage prevention. Suitable for storage tanks, reaction cauldrons and other equipment, safe, reliable and intuitive reading, need to check tightness and glass wear regularly, ensure long-term stable monitoring of liquid medium position.