Liquid CO2 Tanks storage is very useful in the case of large plants. They keep CO2 cold and a liquid so it can be used in a lot of places. Let’s find out how these Derksen liquid storage tank work, why they are useful and why individual tanks are under threat.

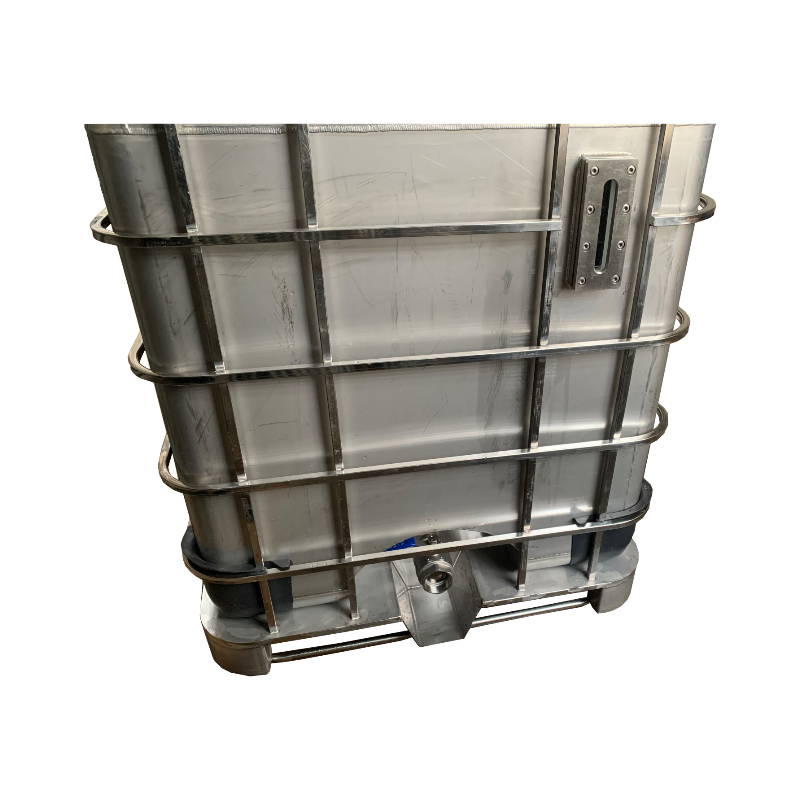

— Liquid CO2 storage tanks are well-suited to factories; they take up little space and keep a lot of CO2. That way factories can conserve space for whatever they need and have plenty of CO2 to spare. What’s more, liquid CO2 is more readily transported and stored than CO2 gas. This makes it safer and more convenient for factories to deploy.

Because working with CO2 can be a dangerous endeavor – not no mention that you wouldn’t want to burn your face off – safety is paramount. Liquid CO2 storage tanks are designed to be safe. They are constructed with durable materials and with safety features to avoid injury. It is also a necessity to keep the tanks in good condition for preventing any issues. That way, factories can operate safely and efficiently.

It’s important to know how to properly store and handle liquid CO2. Derksen tank liquid storage must be kept cold to prevent the CO2 from gassing out. I'm sure you want to be careful with the CO2 and all the safety concerns to avoid accidents. If people know what to do with liquid CO2 and how to process it inside the factory, they will let everything go smoothly.

Big factories can do many kinds of things with liquid CO2 in tanks. Derksen liquid tank storage can also be used to produce fizzy drinks, cool machines and even clean equipment. Because factory need a large amount of liquid CO2 which is widely used. Stored in tanks as a liquid, instead of gas, CO2 can be employed in a variety of ways by factories.

If we want to ensure that liquid CO2 storage tanks work properly, we need to inspect them regularly. That means checking for leaks, maintaining a clean tank and testing safety devices. By maintaining the Derksen bulk liquid tanks well, factories can function better and avoid problems.

We possess 90% self-produced products, allowing us to control costs from the source,.We have 10 years of experience in the productionAnd serving more than 20 countries and regions .

We have an excellent service team. It includes sales, production, quality inspection, logistics, after-sales and other departments to ensure the best and quickest completion of customer orders.

We have a complete product supply chain, from stainless steel raw material opening, stamping, cutting, bending, welding, assembly, we are independently completed.

Our factory covers an area of 10,000 square meters.We have Numbers Of Bending Machine, Punching Machine, Laser Cutting Machine, Automatic Argon Arc Welding Machine,Meet All Kinds Of Customer Customization Requirements. The production capacity can reach 100 units per day