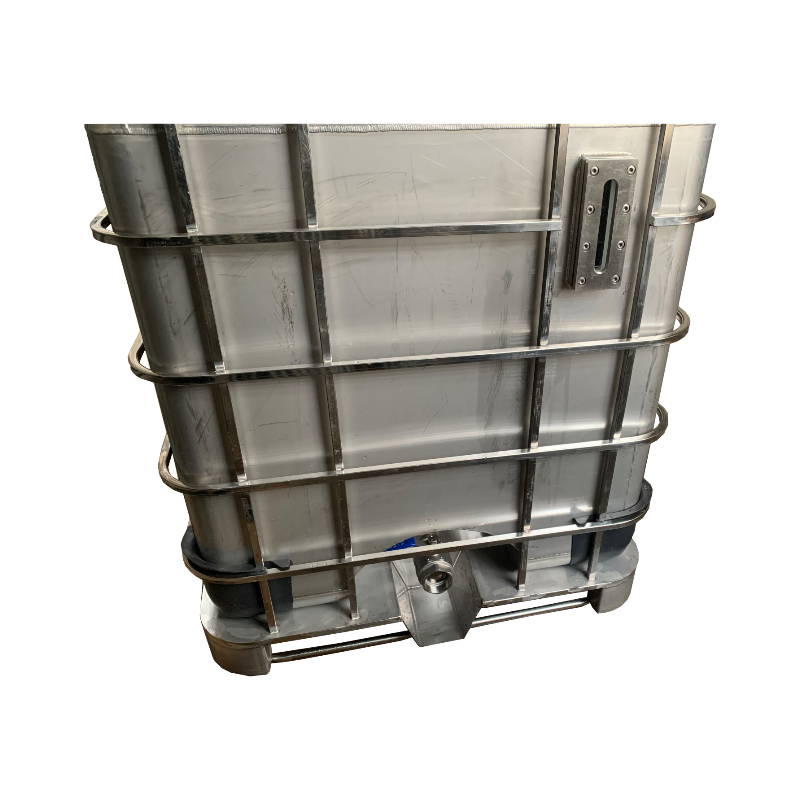

Chemical storage totes : Custom crates to securely transport hazardous chemicals. These totes are available in various shapes and sizes, so they can be used with different types of chemicals. Derksen has a wide range of chemical storage totes perfect for schools, labs and anywhere that houses hazardous materials.

There are many advantages of chemical storage totes. First, they help to keep workers safe by offering a safe means to store and transport hazardous chemicals. Using these totes can help avoid accidents and spills that could harm people and the environment. What’s more, chemical storage totes are strong and durable, so they will last a long time, saving you money down the road.

It is essential to find clever, and space-saving possibilities for storing chemicals in schools and laboratories. Derksen’s chemical liquid storage tank are designed to save space while storing a large quantity of chemicals. That way, you can store more chemicals in a smaller space, keeping your workspace neat and productive.

Various storage options for hazardous materials are very important for institutions that store a large number of chemicals. A year ago I was walking around through a co-op and saw one laying up against a wall! Derksen has one of many different chemical storage totes with extras like stackable, wheel-able or spill-catching trays. That way, you will be able to locate the ideal tote bag for your situation.

You have to make sure your employees and the planet are safe, and the best chemical storage totes is one of the essential tools to help you do that. Derksen liquid bulk tank are constructed out of durable materials that won't rust, leak or contaminate your chemicals. This will prevent accidents and keep your employees safe when it comes to working with chemicals.

Simplifying your chemical handling with storage totes allows you to work more efficiently and more effectively. Derksen's tank liquid storage are easy to use and maintain, freeing you from the burden of extra work and time. And with easy-to-read labels, tight lids, and quick-connect valves, no chemical is a problem.

We have an excellent service team. It includes sales, production, quality inspection, logistics, after-sales and other departments to ensure the best and quickest completion of customer orders.

We possess 90% self-produced products, allowing us to control costs from the source,.We have 10 years of experience in the productionAnd serving more than 20 countries and regions .

Our factory covers an area of 10,000 square meters.We have Numbers Of Bending Machine, Punching Machine, Laser Cutting Machine, Automatic Argon Arc Welding Machine,Meet All Kinds Of Customer Customization Requirements. The production capacity can reach 100 units per day

We have a complete product supply chain, from stainless steel raw material opening, stamping, cutting, bending, welding, assembly, we are independently completed.