Think of the IBC Tote as a big box which contains a bunch of liquid. It is like an enormous flat-bottomed bucket. This base allows people to move the ibc tote tank easily with a forklift. IBC Totes are great for transporting and storing liquid in large quantities.

If you have a lot of liquid you need to move from one place to another, Derksen IBC Totes can help you get it done fast and easy. Rather than have to transport countless small pails and bottles one by one, you can empty all that liquid of the IBC Tote and simply haul it all in one. The perfect solution for cleaning up chemical spills, interior and exterior painting, delivery, and movingDaytons, withstand inclement weather: rugged, will not rust, dent, corrode or fade excellent product to use. This is a time saver and requires less effort.

Learning how to reuse IBC Totes Who knew you could use a ibc totes for sale again and again! You can wash them out and refill them with more liquid instead of trashing them after a single use. This goes a long way to cutting down on waste and saving our planet. Repurpose IBC totes for a great way to watch over liquids and the planet.

There’s not always enough space at work to keep all the liquid containers. That’s why the space-efficient design of the IBC Tote is valuable. The Derksen ibc tote water tank is large and tall, so it occupies less floor area than a lot of smaller containers combined. Using IBC Totes Can Give You More Space in Your Workspace

IBC Totes are widely used in business to store and transport liquids. From the field to the food truck, stainless steel ibc tote make food work easier. These Derksen containers can help enterprises save time, cut costs and reduce overhead. IBC Tote are revolutionizing the way businesses work, facilitating liquid management in a compact and convenient manner.

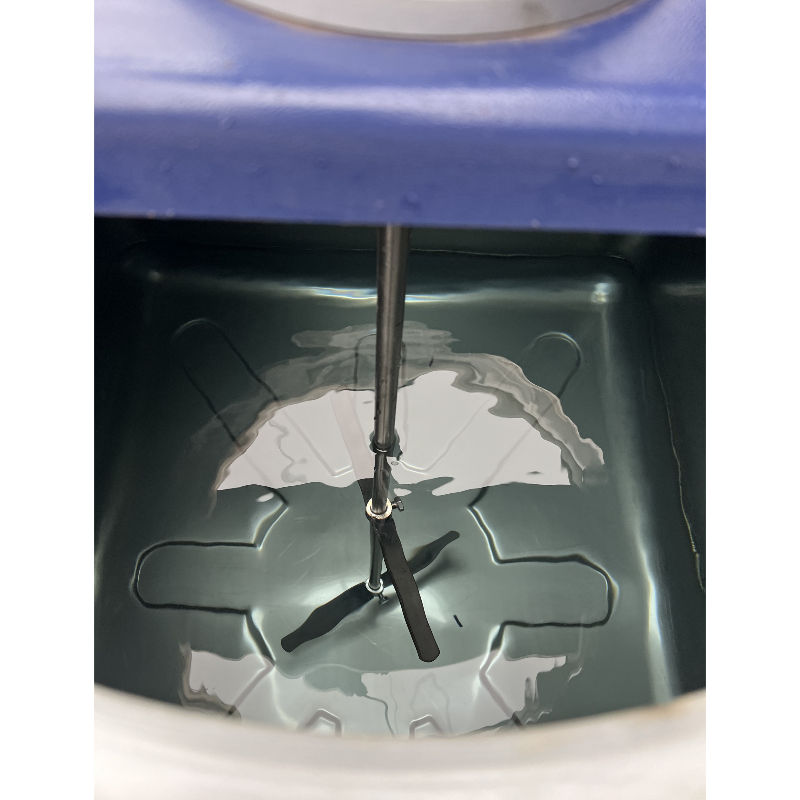

Our factory covers an area of 10,000 square meters.We have Numbers Of Bending Machine, Punching Machine, Laser Cutting Machine, Automatic Argon Arc Welding Machine,Meet All Kinds Of Customer Customization Requirements. The production capacity can reach 100 units per day

We possess 90% self-produced products, allowing us to control costs from the source,.We have 10 years of experience in the productionAnd serving more than 20 countries and regions .

We have a complete product supply chain, from stainless steel raw material opening, stamping, cutting, bending, welding, assembly, we are independently completed.

We have an excellent service team. It includes sales, production, quality inspection, logistics, after-sales and other departments to ensure the best and quickest completion of customer orders.